|

|

| ‧Your Position:TAIWAN NICKEL PRECISION TECHNOLOGY CO., > Product Flow | |||||||||||||||||||||||||||||||||

| ProductFlow | |||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

|

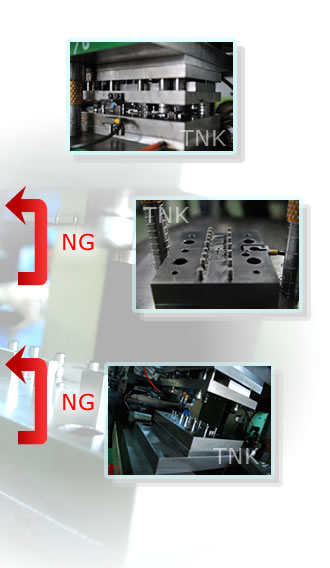

Tooling design process(Development assessment) 1. Providing 3D or 2D drawings or samples. 2. The drawings or samples are according to the clients, we will fully understand what clients needs. 3. Tooling development assessment: tooling demand, product, accuracy and time requirements→ Estimate. 4. According to the clients who provided by the pictures, samples for the development review and analyze. Reply clients a variety of design messages, and advise clients to do the most appropriate type of mold. Tooling design process (Formal development) 1. Draw upon confirmation by the clients, check materials and tolerances, and start operation. 2. After determining the clients' orders, conduct discussion with the production department and schedule delivery according to the customers' needs. 3. Production dept received order, after with technical dept discuss the process and keep track of scheduled processing to completed the process within the specified date and open tooling application form, filing mold resume to ensure customer satisfaction period. 4. Technical dept follow up the date of schedule, and arrange flowsheet design, review, drawing. 5. Final review and discussion by the technical dept after print out the drawing and start tooling process. 6. Do the most careful examination of machining parts. 7. Check and confirm the number and size of tooling, and start assembly. 8. Quality control dept will check all the materials and machines, after all inspection we will start producing. 9. we will deliver samples to customers after the confirmation and measurement is correct, After confirmation of acceptance by the clients and the finished size data collection, pending clients orders and production. |

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||